Process

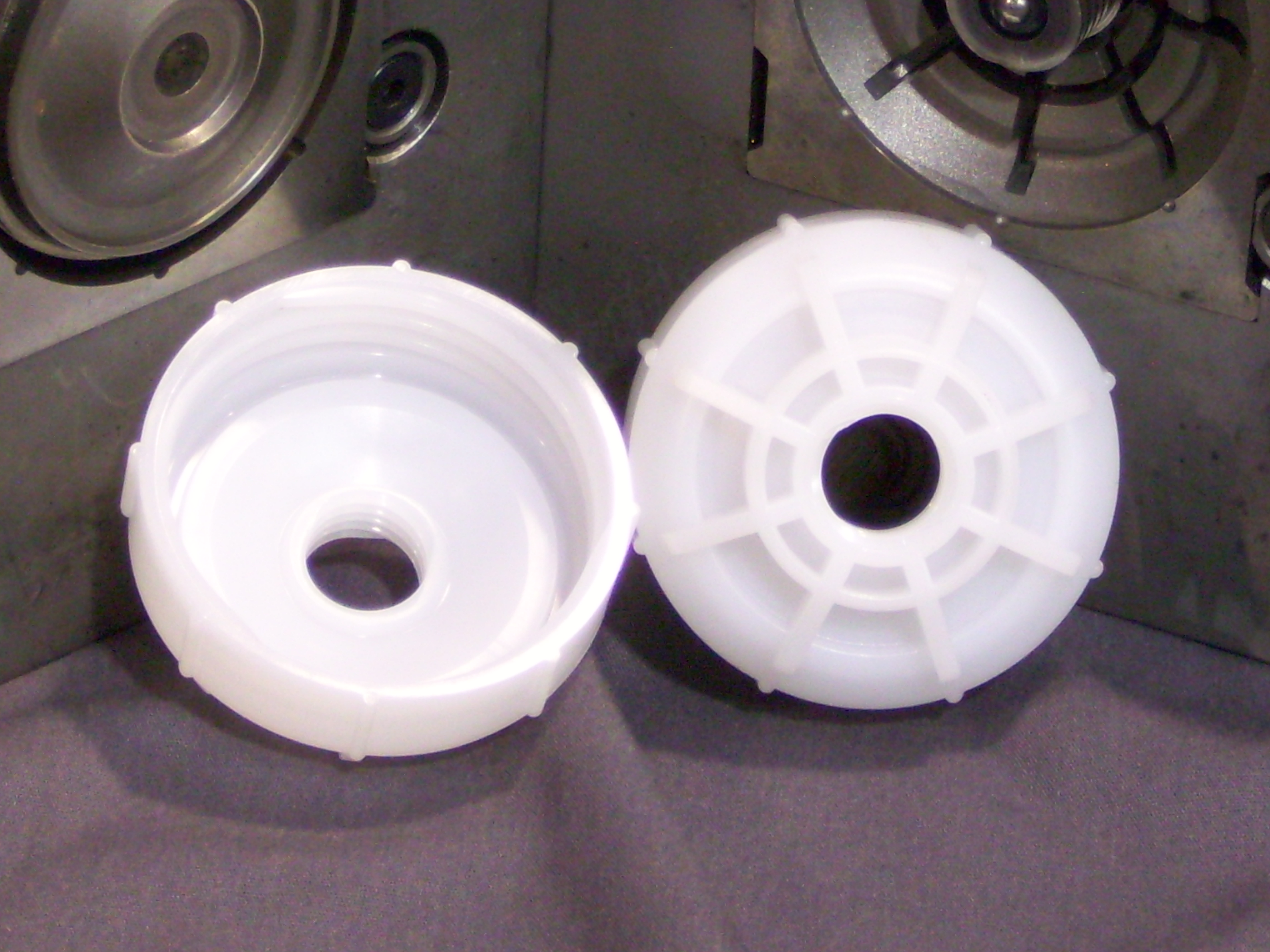

Plastic material in the form of granules is melted until soft enough to be injected under pressure to fill a mold. The result is that the shape is exactly copied.

The molten plastic that has been melted from pellet form in the barrel of the molding machine is injected under pressure into the mold.

After the molten plastic has been injected into the mold, pressure is applied ensuring all cavities are filled. The plastic parts are then allowed to solidify in the mold. The moving platen moves away from the fixed platen separating the mold tool. Rods, a plate, or air blast then aids ejection of the completed plastic molding from the injection mold tool. The length of time from closing the mold to ejecting the finished plastic molding is the cycle.

Clean Room Molding with Geothermal Controlled Process Loop

Automated Molding Process

Automated Molding Process

All Inspection Equipment is Calibrated

Over Molding/Insert Molding Process

In Process Inspection